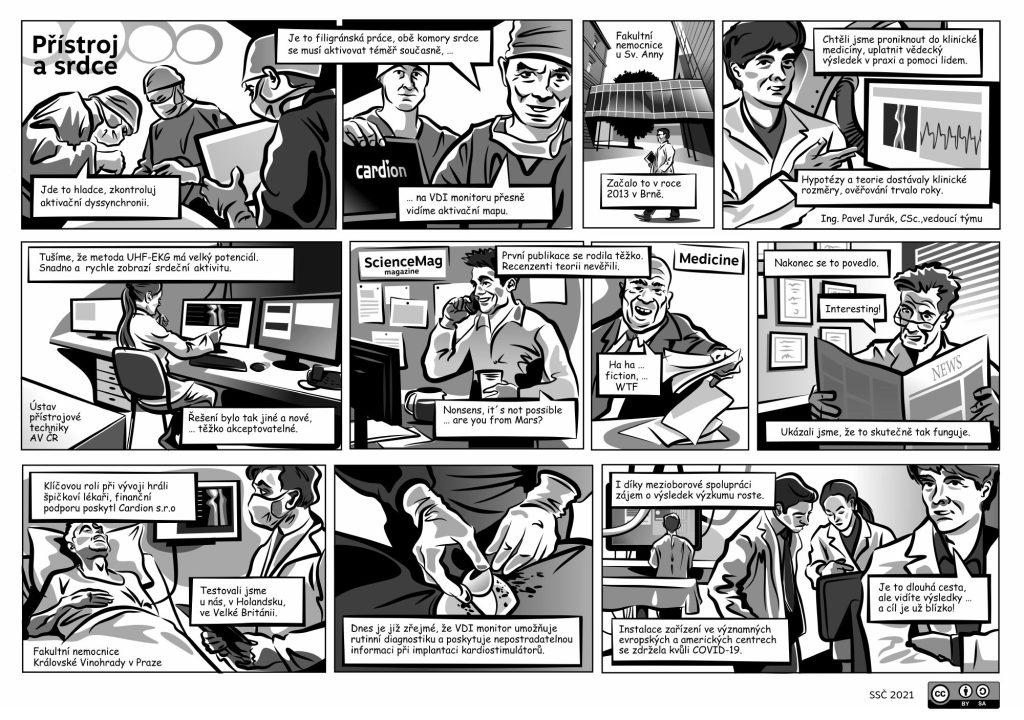

The VDI monitor called Ventricular Dyssynchrony Imaging, using ultra-high-frequency ECG recording, can work in three ways. Either as a diagnostic prior to pacemaker implantation to determine if the patient is suitable for this type of procedure, or it can be used as an aid in setting up the pacemaker itself. However, the greatest use of the device is directly during the procedure to determine the appropriate position of the pacemaker electrode in the heart. When the physician sees the high-frequency maps that the monitor can produce in real time, it helps him or her get a better view of how the pacemaker has worked and can determine the optimal electrode configuration during surgery.

High-frequency maps not only reveal which part of the heart is activated earlier and later during pacemaker insertion, but they also allow us to see how large the relative delay is. When the heart is healthy, the entire volume of both ventricles is activated almost instantaneously. But when there is a problem, for example a patient has had a heart attack, some part of the heart activates earlier and some activates later, and the VDI monitor is able to detect this.

The development of the device is a collaborative effort of Institute of Instrumentation of the CAS, St. Anne’s University Hospital in Brno, University Hospital Královské Vinohrady in Prague and the private company Cardion s.r.o.

Answers to the questions of CeTTAV Ing. Pavel Jurák, Ph.D., Head of the Medical Signals Department, ISI CAS.

You are a direct participant in this transfer story, how would you comment on it? What did it teach you?

You just can’t do it without patience and conviction that it works. It is important that there is trust and the ability to listen to the other party’s requirements. Then new technologies can be effectively combined with practical applications.

We often encounter the opinion that there is still a big gap between business and academia, there is no common language and often no will to understand each other. In the case of your scientific work, it seems exactly the opposite. What is your recipe for a collision-free cooperation between science and business?

Mistakes can be found on both sides. Academia often does not provide topics suitable for practice and does not realise the difference between a proof of principle and a commercial product. The private sector often does not believe in the prospect of specific research and fails to appreciate its potential. However, it is important to realise that it is quite common for something to go wrong. On the contrary, successful collaborations culminating in a final product are not common. So it is not enough to have an idea, the key is the link between the research department, the application department and the funding. If everything works out (even humanly), then it can work.

What are the pitfalls of transferring research results in the field in which you work?

The biggest pitfall is the need for certification as a medical device. Without this certification, the product cannot be offered for clinical use. The latest European legislation is very strict and restrictive in this respect, especially for smaller manufacturers.

A great advantage of testing VDI technology is the fact that the individual installations are carried out on the basis of active cooperation with doctors who are leaders in their field and show an extraordinary interest in the new technology.

The VDI monitor is currently in the experimental phase with CE certification (can be safely attached to the patient) and is being validated at clinical sites. The number of these sites is growing dynamically. The technology is currently being tested in 4 hospitals in the Czech Republic, as well as in the Netherlands and the UK. Further installations are ready in the USA and the Czech Republic.)

What are you looking forward to in the near future?

We are testing new methods that will add additional information to the VDI monitor. It’s quite interesting. And we also look forward to working with other cardiology centers. We have also made contact with another acquisition system manufacturer in the Netherlands and are testing the possibility of expanding the technical base of the VDI monitor.

Thank you for the interview.

Using the materials and under the kind supervision of Ing. Pavel Jurák, Ph.D. Mr. Jurák is the head of the department and has two newly established groups under his supervision https://www.isibrno.cz/cs/medicinske-signaly.

This article can also be found on the ISI website.